-

Traditional

WHAT IS A TRADITIONAL RUG? Traditional rugs typically draw inspiration from either Oriental and Persian patterns or European and Victorian styles. These types of rugs are often described as ornate and intricate in both markings and colour.

-

Modern

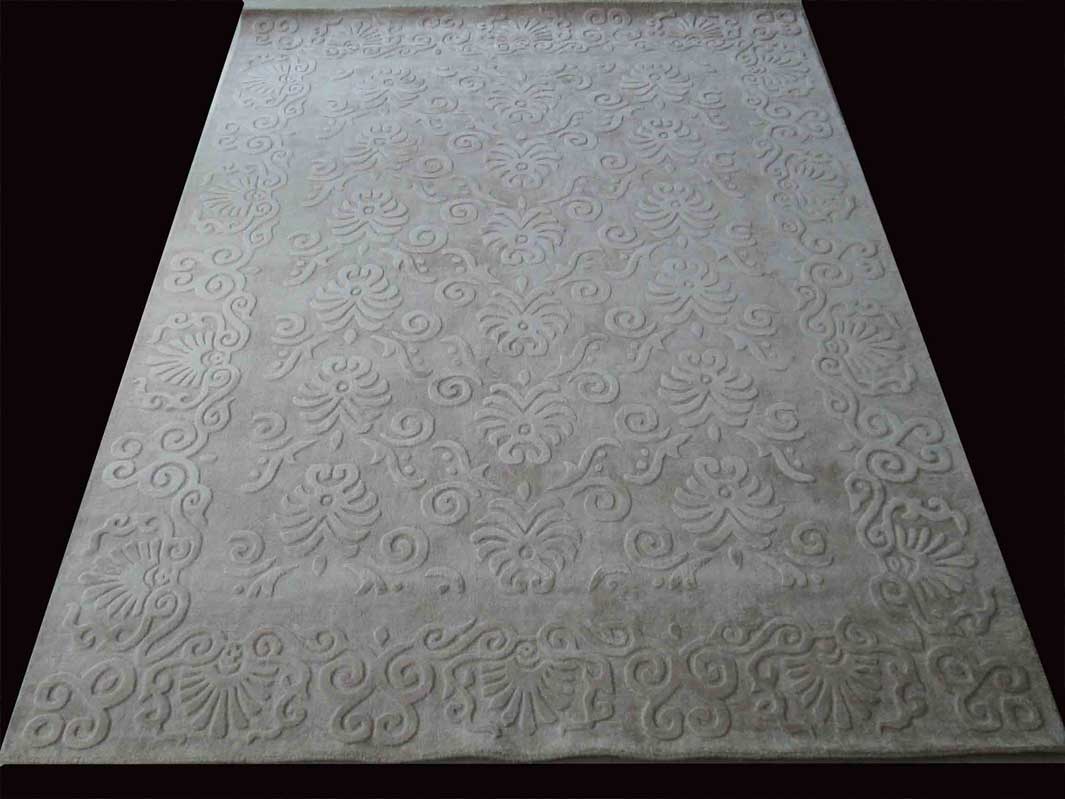

Tibetan rugs are a favorite choice of interior designers and are very different from a traditional Persian hand-knotted rug. Often collectors or designers who love Tibetan rugs, adore them because they are hand-knotted from the wool of sheep that graze in the highlands of Tibet. Tibetan wool is rich in lanolin and once woven can be one of the softest textures ever your feet can encounter. Not really like the Wool Shag rugs but it does resemble the Wool and Silk rugs in their feeling.

-

Handloom

Hand loomed rug is traditionally handwoven on a vertical loom with a mounted wrap. They often have no fringes or proper secured ends or sides. The making of them is by pressing strands of fiber together by using thin threading. The thickness of the rod determines the depth of the pile height. The weaving technique is as such that the designs are limited to certain restrictions. However, they can have a beautiful loop pile, cut pile or a mix of both in them.

-

Flatweave/ Dhurrie

Flat-weaves do not have a pile, because they are woven on a loom. Flat-woven rugs are made by hand or machine by weaving vertical yarns (warps) through the horizontal yarns (wefts). Because they are not woven onto a backing, the rugs are reversible.

-

Jute/Yute Rugs

Jute is a long and shiny grass found in Asia, which is woven to form a beautiful jute carpet or rug. It is well known and popular as “golden fiber” due to its color and cost-effectiveness. The interesting part about growing jute fiber is that they hardly need any fertilizers or pesticides. The stems after harvested from the plant, are steeped into the slow running water orderly to allow for bacteria for dissolving the adhesive materials holding the fibers together. Then, the non-fibrous materials are scrapped off in a process that is known as “Stripping.” Furthermore, these are separated and then washed, dried, graded and then sent to Jute mills, where they are again processed into Jute yarn